CNC Milling: Why Use it Over Traditional Milling Process?

Milling is one of the important machining processes. It removes material from the workpiece via a rotary cutting process. Traditionally, it was performed by using milling machines. Over the years, computer numerical control (CNC) milling has replaced traditional milling in various industrial segments. CNC milling is widely employed in various manufacturing facilities to produce gears, washers, electronic components, and more. Similar to other CNC-operated machining processes, CNC milling has gained immense popularity in recent years. However, before getting into CNC machining, it is important to know what exactly it has to offer over traditional milling. This post discusses why using CNC milling can be a beneficial choice.

Introduction to CNC Milling

CNC milling is a computer numerical controlled milling process. It utilizes a CNC automated setup that performs material reduction by generating a rotating action of multipoint cutting tools wherein the workpiece remains fixed. The operation of material removal in CNC milling is absolutely similar to traditional milling. However, CNC milling is an automated process that operates by referring to a CNC program set into the control panel. In this process, the CNC G-code and M-codes are used to schedule and direct the milling operation. A CAD design of the desired product is referred to develop a CNC program. This can include inclination of a multipoint tool, milling speed, movement of the tool along the specific axis (X, Y, or Z-axis).

Benefits of CNC Milling over Traditional Milling

The following benefits of CNC milling make it superior to traditional

- CNC milling is an automated process. Once the program is set, the machine operates on its own. This reduces the need for human assistance.

- Close dimensional accuracy can be achieved in CNC milling.

- CNC milling can be operated along multi-axes. It can be done with a 3-axis or 5-axis rotation of the multipoint cutting tool. This allows effective face milling, plain milling, angular milling, and form milling.

- CNC milling follows the CAD prototyping, therefore the design and dimensions of the products are approved prior to the milling process. This gives additional security to the production cycle as the scope for failure is nullified during the prototyping. The tolerance in CNC milling ranges between ± 0.001 inches and ± 0.0005 inches.

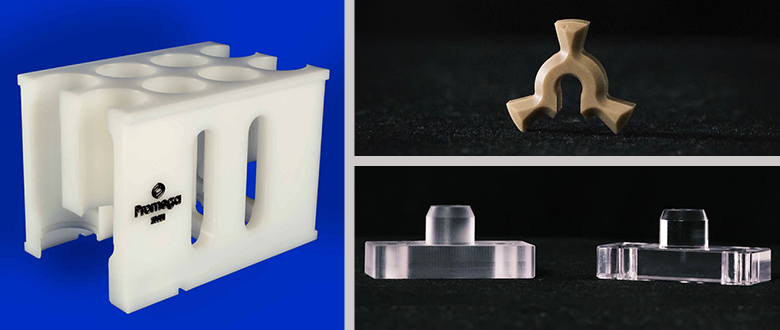

- CNC milling is compatible with a wide variety of materials including metals, plastics, silicon, composites, etc.

Since the superiority of CNC milling over traditional milling is well-persuaded, you can consider it for your next project. However, to ensure the quality of milling production, you should source these services from only reliable suppliers like Brogan-Patrick. The company offers precision CNC machining services and CNC milling is one of their most popular machining services.