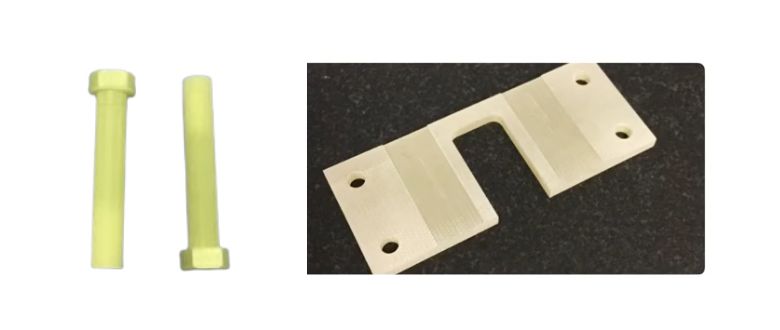

Plastic is often used as a covering or insulator material for many electrical devices as it is a bad conductor of electricity. But, not all plastics can be used in this way. Only plastics with certain properties such as resistance to heat, vibration, and so on find applications in this segment. G10 and FR4 are high-pressure glass-reinforced industrial laminates made from glass fabric impregnated with epoxy resin. They are commonly used as insulating materials for electrical devices, and some of these grades are certified by NEMA. The NEMA grades of FR4 are a fire-retardant grade of G10, and hence the latter can be replaced for such fire-sensitive applications, including for components in a nuclear reactor, unless G10 is specified for use. Brogan & Patrick offers G10 machining and FR4 machining services, and we machine several variants of these to offer you the required quality and specification of machined parts. Additionally, we offer cryogenic deburring for a fine finish of your parts.

G10 FR4 material is made by impregnating an electrical glass cloth with an electrical-grade epoxy resin, and treating it at certain heat and pressure. Here are some of the properties of this material, which make them popular among our industrial clients.

• G10/FR4 have high mechanical strength and low water absorption capacity, and this is one reason they are used in electrical applications.

• G10/FR4 functions well in a wide temperature range without any changes to their mechanical strength and dimensional stability.

• The grade can be easily machined to the required size, shape, and dimensions.

• The material possesses excellent resistance against chemicals, abrasion, and heat; therefore, their wear and tear is relatively slow.

• G10/FR4 is also used in mechanical applications that demand excellent stiffness, strength, as well as creep resistance.

• The material possesses an excellent flammability rating and is UL listed.

Here are some of the industries where our G10 material machining parts are used:

• Electrical Industry: G10 FR4 is widely used in the electrical industry for its excellent insulating properties and resistance to electrical arcs. It is an ideal material for manufacturing electrical insulators, circuit boards, and components that require electrical insulation and stability.

• Oil and Gas Sector: In the demanding and often harsh environments of the oil and gas industry, G10 FR4 machined parts are valued for their resistance to corrosion, chemicals, and extreme temperatures. They are used in the production and maintenance of equipment such as valves, gaskets, and seals.

• Marine and Underwater Applications: The marine and underwater industry benefits from G10 FR4 due to its water-resistant properties, high strength, and corrosion resistance. It is employed in the construction of marine components like shipboard electrical systems, underwater sensors, and submersible equipment.

• Aerospace Industry: In aerospace applications, where lightweight and high-performance materials are essential, G10 FR4 stands out. It is utilized in aircraft components, including radomes, insulating materials, and electrical connectors, ensuring reliability in the most demanding conditions.

• Semiconductor and Electronics: G10 FR4 is a staple in the semiconductor and electronics industry. It serves as a substrate material for printed circuit boards (PCBs), providing excellent electrical insulation and mechanical stability, vital for the performance of electronic devices and gadgets.

• Instrumentation: Precision and reliability are paramount in instrumentation. G10 FR4 machined parts find their way into instruments and equipment used for measurement, control, and analysis, where their dimensional stability and resistance to environmental factors are highly valued.

• Telecommunication: In the fast-paced world of telecommunications, G10 FR4 plays a crucial role in the construction of antennas, RF (radio frequency) components, and communication infrastructure. Its electrical properties ensure signal integrity and durability.